- 服务热线

手机:13789806976

地址:山东省济南市全福立交桥东100米路北(工业北路301号)通运汽配城3排15、16号 4排15、16号)

邮箱:13789806976

在高端汽车领域,奔驰以精密工程与卓越性能著称,其保养维护需建立科学化、精细化的养护体系。从机械系统到电子模块,从常规保养到深度养护,车主需掌握六大核心维度,确保车辆始终处于最佳状态。

In the high-end automotive field, Mercedes Benz is known for its precision engineering and excellent performance, and its maintenance requires the establishment of a scientific and refined maintenance system. From mechanical systems to electronic modules, from routine maintenance to deep maintenance, car owners need to master six core dimensions to ensure that their vehicles are always in optimal condition.

一、养护周期的精准把控

1、 Accurate control of maintenance cycle

奔驰官方保养手册将保养周期分为A保、B保两大类:

The official maintenance manual of Mercedes Benz divides the maintenance cycle into two categories: A maintenance and B maintenance:

A保(基础保养)

A Guarantee (Basic Maintenance)

每行驶1万公里或12个月进行,核心项目包括机油机滤更换、全车油液检查、轮胎气压校正等。采用低粘度全合成机油,可提升燃油经济性3%-5%。

Every 10000 kilometers or 12 months of driving, the core projects include oil filter replacement, full vehicle oil inspection, tire pressure correction, etc. Using low viscosity fully synthetic engine oil can improve fuel economy by 3% -5%.

B保(深度保养)

B Guarantee (Deep Maintenance)

每行驶2万公里或24个月实施,涵盖空气滤清器、空调滤清器、刹车油、火花塞等18项检测更换。在涡轮增压车型中,需额外进行中冷器清洁与增压管路检查。

Implemented every 20000 kilometers or 24 months, covering 18 tests and replacements such as air filters, air conditioning filters, brake oil, spark plugs, etc. In turbocharged models, additional cleaning of the intercooler and inspection of the boost pipeline are required.

二、关键系统的专项养护

2、 Special maintenance of critical systems

对核心部件实施预防性维护,可延长使用寿命:

Implementing preventive maintenance on core components can extend their service life:

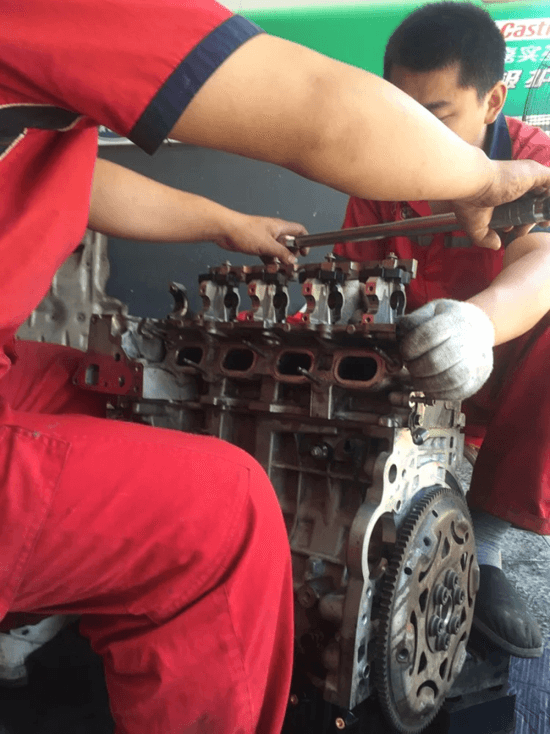

动力总成养护

Powertrain maintenance

采用纵置布局的发动机,需每3万公里进行缸内积碳清洗。使用核桃砂物理清洗技术,避免化学清洗剂对氧传感器的腐蚀,恢复发动机压缩比至设计值±2%。

An engine with a vertical layout requires carbon cleaning of the cylinder every 30000 kilometers. Use walnut sand physical cleaning technology to avoid corrosion of the oxygen sensor by chemical cleaning agents and restore the engine compression ratio to the design value ± 2%.

传动系统维护

Transmission system maintenance

9速自动变速箱需每6万公里更换专用油液,采用等量交换法,确保油液填充量精确至±0.2L。对四驱车型,需检查分动箱油位与传动轴防尘套完整性。

The 9-speed automatic transmission requires the replacement of specialized oil every 60000 kilometers, using an equal amount exchange method to ensure accurate oil filling to ± 0.2L. For four-wheel drive models, it is necessary to check the transfer case oil level and the integrity of the transmission shaft dust cover.

底盘系统调校

Chassis system calibration

每行驶4万公里进行四轮定位参数校准,重点调整前束角与外倾角。对配备空气悬架的车型,需使用专用诊断仪进行高度传感器校准,误差控制在±1mm以内。

Perform four-wheel alignment parameter calibration every 40000 kilometers, with a focus on adjusting the toe angle and camber angle. For vehicles equipped with air suspension, a dedicated diagnostic instrument is required for height sensor calibration, with an error controlled within ± 1mm.

三、电子系统的深度检测

3、 Deep detection of electronic systems

现代奔驰车型搭载30余个电子控制单元,需定期进行软件更新与硬件检测:

Modern Mercedes Benz models are equipped with over 30 electronic control units, which require regular software updates and hardware testing

诊断仪全扫描

Diagnostic instrument full scan

使用奔驰原厂诊断仪STAR D,对CAN总线、LIN总线、MOST总线进行通信质量检测。重点监控发动机控制模块、变速箱控制模块、车身控制模块的故障码存储情况。

Use the Mercedes Benz original diagnostic tool STAR D to perform communication quality checks on the CAN bus, LIN bus, and MOST bus. Focus on monitoring the fault code storage status of the engine control module, transmission control module, and body control module.

软件版本管理

Software version management

每12个月进行控制单元软件升级,优化发动机标定、变速箱换挡逻辑、能量回收策略等参数。实测显示,软件升级可使综合油耗降低2%-4%。

Upgrade the control unit software every 12 months to optimize parameters such as engine calibration, transmission shift logic, and energy recovery strategy. Tests have shown that software upgrades can reduce overall fuel consumption by 2% -4%.

传感器校准

Sensor calibration

对毫米波雷达、摄像头、超声波传感器等22类传感器进行动态校准。在自适应巡航系统中,需确保雷达波束角度偏差<0.5°,保障驾驶辅助系统的可靠性。

Dynamically calibrate 22 types of sensors, including millimeter wave radar, cameras, and ultrasonic sensors. In the adaptive cruise control system, it is necessary to ensure that the radar beam angle deviation is less than 0.5 ° to ensure the reliability of the driving assistance system.

四、易损件的预防性更换

4、 Preventive replacement of vulnerable parts

建立易损件寿命数据库,实施精准更换:

Establish a database for the lifespan of vulnerable parts and implement precise replacement:

制动系统

brake system

刹车片摩擦材料厚度<3mm时需更换,采用低金属配方刹车片,可减少粉尘排放40%。对配备陶瓷刹车盘的车型,需使用专用工具进行盘面平整度检测。

When the thickness of the brake pad friction material is less than 3mm, it needs to be replaced. Using low metal formula brake pads can reduce dust emissions by 40%. For models equipped with ceramic brake discs, special tools are required to perform flatness testing on the disc surface.

轮胎管理

Tire management

采用胎压监测系统(TPMS),实时监控轮胎压力与温度。当胎纹深度<3mm时,需更换为原厂认证轮胎,确保湿地抓地力符合欧盟ECE R117标准。

Adopting tire pressure monitoring system (TPMS) to monitor tire pressure and temperature in real-time. When the tread depth is less than 3mm, it is necessary to replace it with original factory certified tires to ensure that the wet grip meets the EU ECE R117 standard.

滤清器系统

Filter system

空气滤清器每2万公里更换,采用HEPA级滤材,对PM2.5过滤效率达99.5%。空调滤清器每1万公里更换,附加活性炭层,可吸附90%以上的有害气体。

The air filter is replaced every 20000 kilometers and uses HEPA grade filter material, with a filtration efficiency of 99.5% for PM2.5. The air conditioning filter is replaced every 10000 kilometers with an additional activated carbon layer that can adsorb over 90% of harmful gases.

五、特殊工况的应对策略

5、 Response strategies for special working conditions

针对不同使用场景,制定专项养护方案:

Develop specialized maintenance plans for different usage scenarios:

高温环境养护

High temperature environment maintenance

在环境温度>35℃时,需加强冷却系统检测。每2万公里更换冷却液,确保冰点<-35℃,沸点>135℃,防止发动机开锅。

When the ambient temperature is above 35 ℃, it is necessary to strengthen the detection of the cooling system. Replace the coolant every 20000 kilometers to ensure that the freezing point is below -35 ℃ and the boiling point is above 135 ℃, in order to prevent the engine from boiling.

低温环境启动

Low temperature environment startup

在环境温度<5℃时,需使用电加热机油滤清器,预热机油至40℃以上再启动,降低冷启动磨损60%。对柴油车型,需安装进气预热格栅。

When the ambient temperature is below 5 ℃, an electrically heated oil filter should be used to preheat the oil to above 40 ℃ before starting, reducing cold start wear by 60%. For diesel models, it is necessary to install an intake preheating grille.

涉水行驶处理

Handling of driving through water

通过积水路段后,需立即检查空气滤清器湿度。如发现进水,需更换滤清器并对发动机舱进行干燥处理,防止电子模块腐蚀。

After passing through the flooded section, it is necessary to immediately check the humidity of the air filter. If water is found to have entered, the filter should be replaced and the engine compartment should be dried to prevent corrosion of the electronic module.

六、养护质量的溯源管理

6、 Traceability management of maintenance quality

建立数字化养护档案,实现全生命周期追溯:

Establish digital maintenance records to achieve full lifecycle traceability:

电子健康档案

Electronic health records

通过Mercedes me APP,可查看历史保养记录、维修诊断报告、零件溯源信息。对更换的每个零件,可扫描二维码查询生产批次与质检报告。

Through the Mercedes me app, users can view historical maintenance records, repair diagnostic reports, and parts traceability information. For each replaced part, the production batch and quality inspection report can be queried by scanning the QR code.

养护过程监控

Monitoring of maintenance process

在授权服务中心,关键保养工序需通过视频记录存档。如机油加注量、螺栓紧固扭矩等参数,可随时调取复查。

At the authorized service center, critical maintenance procedures need to be recorded and archived through video. Parameters such as oil filling amount and bolt tightening torque can be retrieved and rechecked at any time.

质量反馈机制

Quality feedback mechanism

保养后72小时内,客服中心进行满意度回访。如发现养护质量问题,启动快速响应流程,48小时内完成整改并复检。

Within 72 hours after maintenance, the customer service center will conduct a satisfaction follow-up. If any maintenance quality issues are found, initiate a rapid response process, complete rectification and re inspection within 48 hours.

本文由济南奔驰汽车保养友情奉献.更多有关的知识请点击:http://www.lutongqixiu.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is a friendly contribution from Volvo Car Repair in Jinan For more information, please click: http://www.lutongqixiu.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message